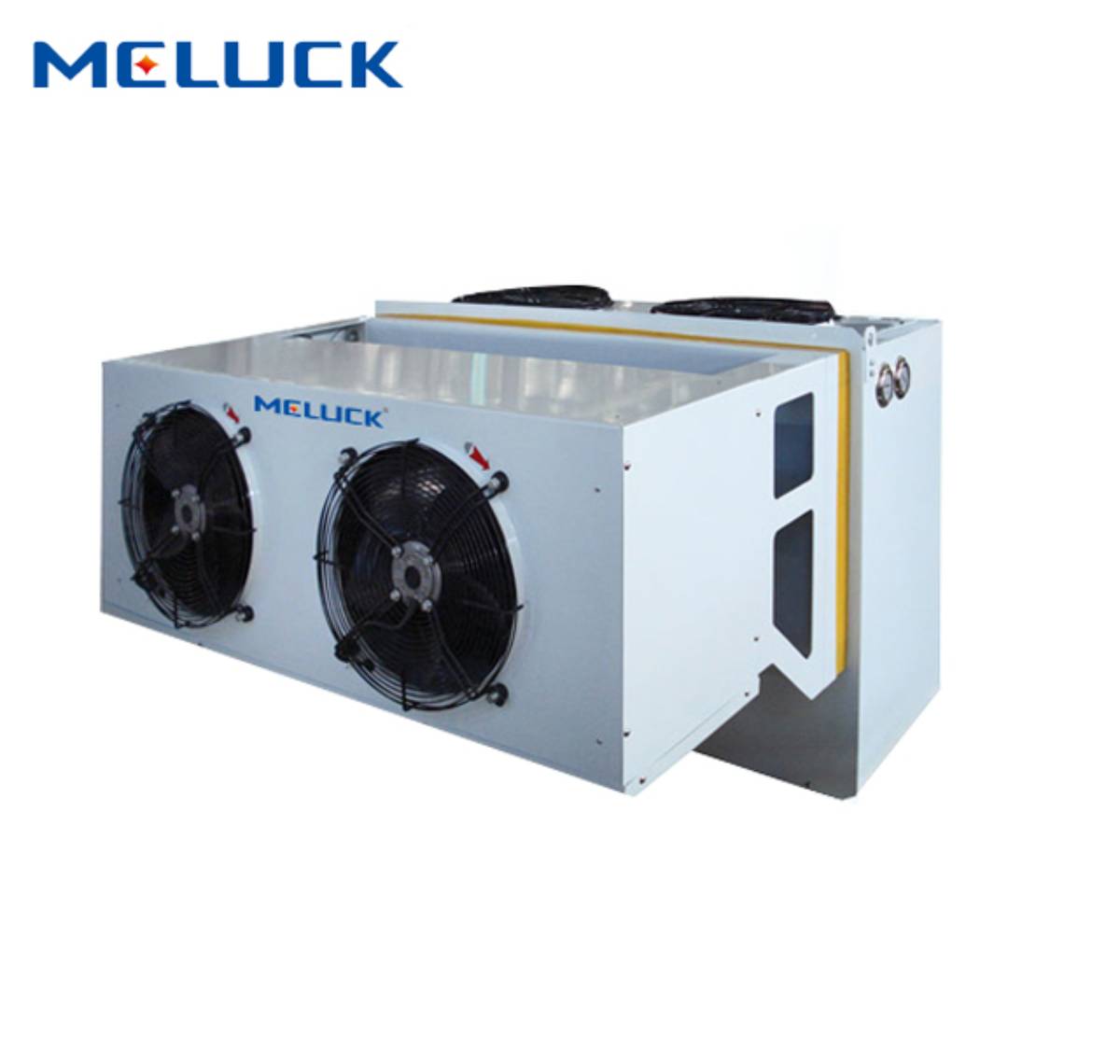

Air Cooled Water Chiller

Air Cooled Chiller

- Compressor:Copeland scroll/Bitzer Scroll

- Cooling: Air or water cooled

- Refrigerant:R22/R404a/R134a/R407C

- Voltage:380V/3PH/50HZ ± 10%

- Description: Application:Food industry, Chemical,Beverage, AC,Plastic injection, Pharmaceutical etc.

Inquiry Now

Parameter:

Descriptions

1.Product Introduction

Chillers, also called industrial chiller units, chilled water plants or chilled water systems, are cooling equipment that produces chilled water and are suitable for a variety of industrial and commercial applications.

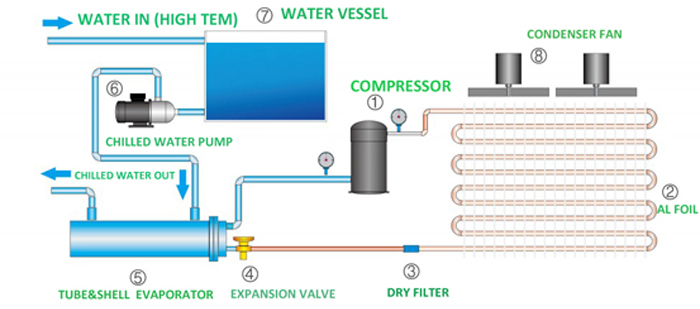

Air Cooled Chiller System Diagram

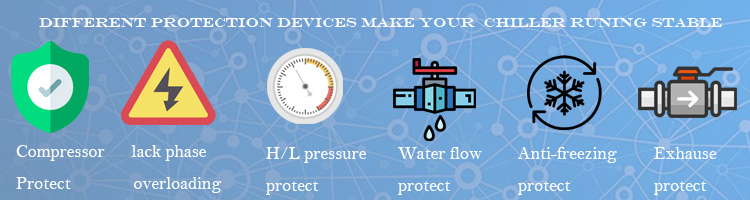

2.Meluck Air Cooled Chiller Features

●Stainless steel tank is equipped inside, high efficiency, low noise.

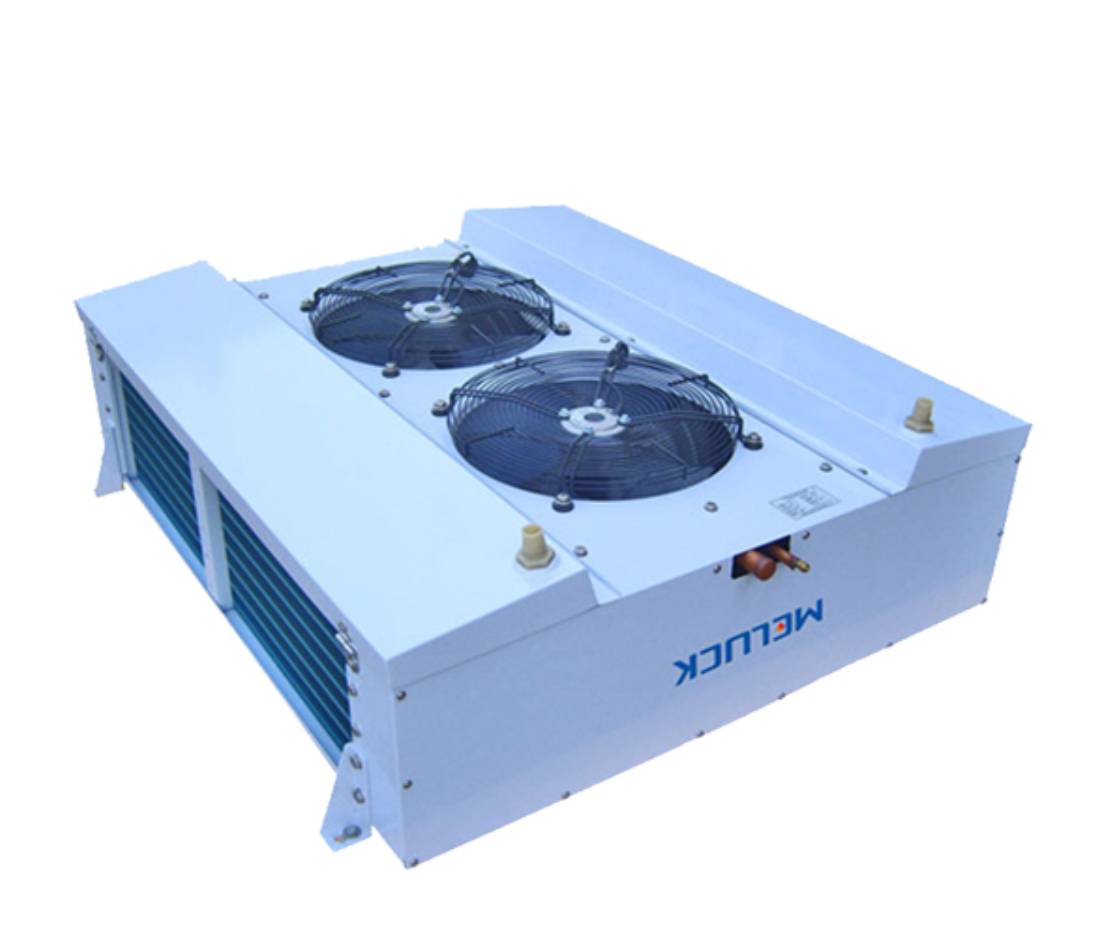

●Condensing fan with bigger flowing capacity, less vibration.

●Moveable with wheels for capacity bellow 35KW.

●Dul systems for capacity above 50KW in case of any one comes error.

●Inverter compressor for energy saving

●Soft-start for compressor protection

●PLC+Touch screen, easy for operation

●Original America and Germany compressor for durable use.

●Capacity: 3tons-500tons

3.Product application

4.FAQ

1.How does a chiller system work?

Chiller has two circulation,one is process water circulation,the other is refrigerant gas circulation.Heat picked up from the process.Heat transfers to refrigerant circulation.Heat is remove to air or water.

2.How to calculate cooling capacity for chillers?

Cooling Capacity(kw)= Flow Rate(m3/h)*Temp Change(T1-t2)/0.86

Heat Load= C(specific heat)* M(quality output per hour )*Temp Change(T1-T2)

3.Types of chiller system?

Air Cooled Chiller and Water Cooled Chiller.Water cooled chiller needs a separated cooling tower and has a higher efficiency,but less easier than air cooled.

4. What type of the chiller should I use ?

It depend on the local environment temperature and water source. If lack of water and low ambient temp , we advise you use the air cooled chiller, if not , air cooled chiller is ok. But for installation,air cooled is more convenient than water cooled.

5. How to select the model of the chiller ?

It is better to tell us some parameter, such as : Cooling Capacity, Outlet Temperature, Power Supply,Environment Temperature, Application Field, Anti-rust Or Anti-corrosion, and so on.Meanwhile,we could do customized chiller according to your end user consumption.

6.Cooling capacity unit conversion?

1 kcal/h = 1.163W,1 W = 0.8598 kcal/h;

1 Btu/h = 0.2931W,1 W = 3.412 Btu/h;

1 USRT = 3.517 kW,1 kW = 0.28434 USRT;

1 kcal/h = 3.968 Btu/h,1 Btu/h = 0.252 kcal/h;

1 USRT = 3024 kcal/h,10000 kcal/h = 3.3069 USRT;

7.The chiller can heat?

Yes,by the electrical heating wire.Please kindly inform us the hot water temp or heating capacity.

8. What is production period ?

Generally speaking, it is 15-30 days,some standard model there are some stocks, but it all depend on the model ,quantity.

9.What is your company after-sales service ?

Our warranty period is one year. If there is any problem in this year, we will send you the new parts for replacement. Meanwhile, welcome to consulting the technical knowledge.

10.Chiller maintenance?

Step 1: Keep Tubes Clean

Step 2: Ensure a Leak-free Unit

Step 3: Sustain Proper Water Treatment(prevent scale, corrosion)

Step 4: Analyze Oil and Refrigerant

Related Products

Inquiry Now

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message

FAQs

We are making our greatest efforts to offer you the quality made products at good price. We’d like to cooperate with you to expand our business in your markets.If in doubt, please see the following FAQs